In the Alfredo Polti SA quarry in Arvigo, we quarry around 18,000 m3 of gneiss per year and transport blocks weighing up to 30 tons. From half of the material we manufacture products for various applications such as horticulture, building envelopes, interior finishing and flooring as well as other custom-made products. Shaped or rectangular slabs and blocks are also sold in their raw state. Of the production, 6-10% is exported, mainly to the neighboring countries of Germany, Italy and Austria. But pieces from the Calanca Valley have also been delivered to Japan or the USA.

What we do is not factory work, but real craftsmanship. This requires not only manpower and know-how, but also horsepower: excavators, dumpers, forklifts, trucks and hydraulic drills form important parts of the infrastructure. From the well-planned excavation to the careful selection of the blocks and the manual stone processing, all work steps are carried out by our long-standing, well-trained team. Quality and safety are among our standards, which is why our company has been ISO-certified since 2007.

We are committed to a mindful approach and appreciation of nature and the environment. In order to reduce the environmental impact to a minimum, we optimize our work processes. In addition, we use diamond wire, blasting and drilling techniques for stone extraction, avoiding classic blasting (0-2 times per year) as much as possible. Of the amount mined annually, one quarter is geological waste and one quarter is technical waste, which is generated during cutting and processing. Of this, 100% is (re)processed into gravel, which is reused both in road construction and for our quarry needs.

Mountains are always on the move. Our quarry presents a challenge with its location and the 30-degree slope in our direction. We are aware of this responsibility and have been working with a sensor system that detects movements at an early stage since 2006. Nevertheless, in addition to the measuring instruments and the professional exchange we have maintained with a geologist for over 20 years, the eye remains our most reliable expert. The amount of precipitation and slope movements determine the intervals at which we check cracks or displacements in the terrain.

Stone is a natural material that can be reused. It occurs in the Alps in large quantities, but unlike wood, it does not grow back. That is why we treat our material with the greatest care. To the layman, a quarry resembles a pile of rubble, everything appears gray. It therefore takes a lot of experience to recognize the fine differences between cracks and veins.

We select the blocks that have a continuous slate and are thus suitable for processing already at the quarrying site. The blocks are then taken to an intermediate storage facility, where they are either deposited as stock or from where they are transported to the workshop for further processing.

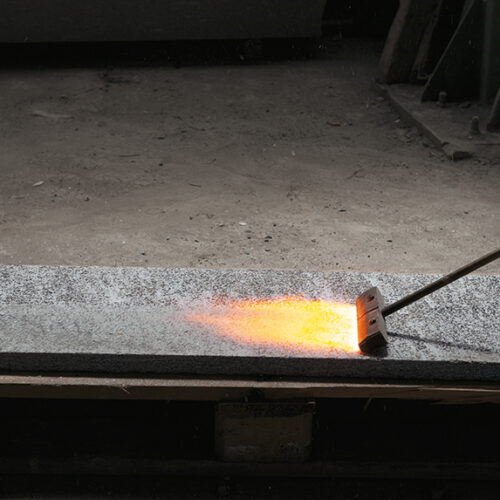

The material is mostly processed in our own factory by our stonemasons, stonecutters, sculptors and machinists in various steps. Gneiss is layered, it is split by hand and broken against the grain. Our team must be able to read the stones and identify fine lines. The stone is either split naturally with nails and hammer blows or separated by diamond and gang saws and polished, honed or brushed with stone working machines.

For slabs with smooth surfaces, circular saws with oversized blade diameters of 3 m, 1.6 m and 1 m are used in the workshop. Nevertheless, stone processing is a task for specialists and requires a sure instinct. In addition to our modern CNC machines, we still use many of the traditional tools. We forge pointing and striking irons, chisels and wedges ourselves. Our blacksmith ensures that the tools fit properly in the hands of each of our employees.

- Fountains

- Pergolas

- Pools and ponds

- Tables

- Palisades and privacy walls

- Masonry

Garden design

- Kitchens

- Fireplaces

- Baths and showers

Interior design

- Facades

- Window sills and thresholds

- Roofing

Facades and roofing

- Exterior flooring

- Interior flooring

- Stairs